By uncovering how its curved surface and electric-field response stabilize key intermediates, this work redefines how carbon nanomaterials can be used in clean energy technologies.

"The findings open new possibilities for designing efficient, metal-free catalysts - which are more sustainable," says Hao Li (WPI-AIMR, Tohoku University), "This work aligns perfectly with global efforts to reduce CO2 emissions and combat climate change."

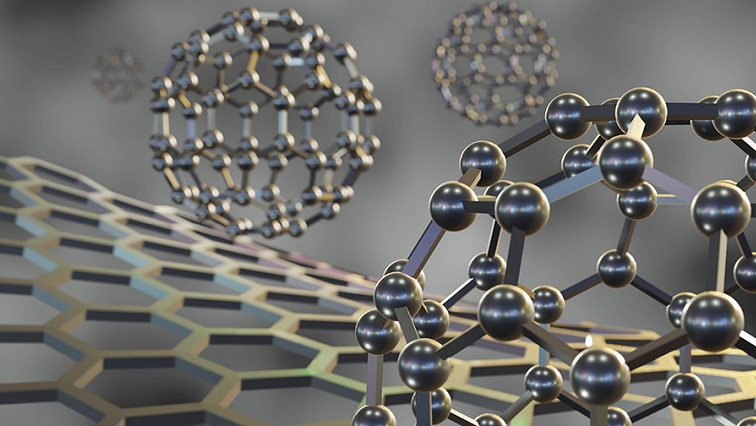

Fullerene is a cage-shaped molecule that has a lot of potential to boost the efficiency of catalytic systems. It works well as an electron buffer, which improves the efficiency of reactions such as hydrogen evolution, oxygen reduction, and carbon dioxide (CO2) reduction. Integrating fullerene into these catalytic systems can greatly improve performance in numerous areas, which positions it as a promising material to promote green technologies. Not only does it improve performance, but it is potentially more affordable than other available options as well.

A research team at Tohoku University used a special model to classify how C60 behaves in order to predict its utility during electrochemical reactions. They found that its unique structure stabilizes COOH* intermediates across different pH conditions. They compared their models with experimental observations to reveal new insights on C60-based catalysts and the mechanisms behind their beneficial activity.

Building on this discovery, the research team's next steps will focus on systematically exploring how surface curvature influences catalytic behavior across various electrochemical reactions. They aim to extend the application of C60 and other curved carbon nanostructures to reactions such as nitrate or nitrogen reduction, and to design hybrid catalysts with tunable curvature. The more their model advances, the better we can take advantage of this useful molecule for producing clean energy.

All the experimental and computational data are also available in the Digital Catalysis Platform (DigCat), the first catalysis digital platform developed by the Hao Li Lab.

Read the original article on Tohoku University.