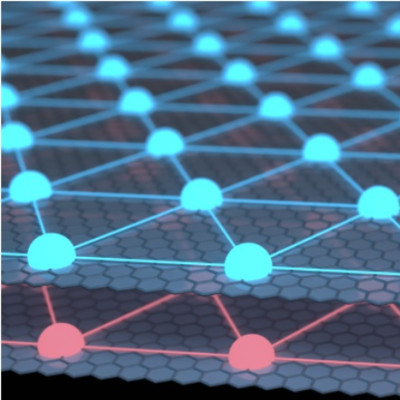

To put it in a simple way, graphene is just a single thin layer of graphite that can be found in pencil lead. While it is an allotrope of carbon, they are arranged in different ways atomically that presents completely different properties in most cases.

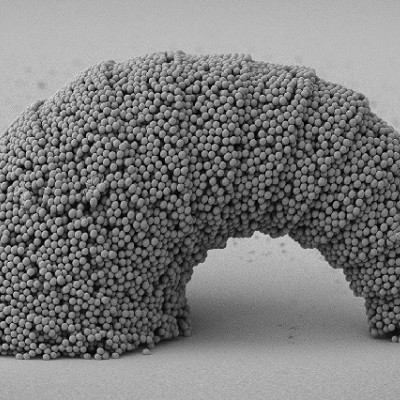

Easier said than done, its low yield and high complexity in the creation of these things have led to a slow R&D process that only in recent years it saw many more discoveries and breakthroughs in practical use cases.

Why MSI would pick this material for the GPUs you said?

Because it is lighter, thinner, and stronger than steel and conducts heat greater than diamonds but still flexible enough to be morphed into various shapes and be made into many types of components.

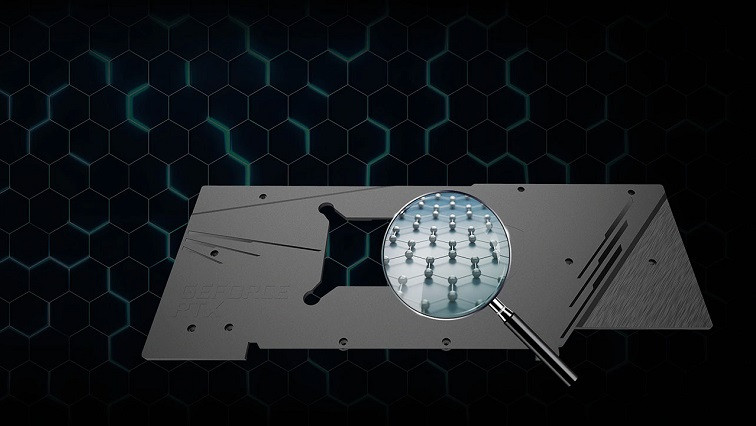

The company has also found that for the RTX 3000 series cards like the RTX 3080 GAMING TRIO, by providing three 8pin power connectors instead of two for consistent power output and leave enough for power spikes cushioning or dampening, the overall design of MSI GPUs need to have uncompromising durability and superior heat transfer to hit the greatest performance possible.

For the usage of graphene parts, it is replacing the backplate traditionally made of plastic that provides greater heat dissipation performance and better stiffness to handle the weight of the entire card while still weighing less than plastics. For MSI, the use of graphene is definitely needed to leverage the increasingly powerful GPUs within each generational leap while providing reinforced durability and conductivity to make sure that the cards work hard and stays alive for a long period as well.

Read the original article on Tech Critter.