Solving the challenges in e-textiles

The promise for producing flexible, light-weight and conformable electronic components for textile goods is huge, and it opens opportunities for electronic-based sensing and energy devices to be incorporated into or embedded into cotton-based substrates. In wearable/flexible electronics, nanostructured smart materials must meet appearance, performance and weight requirements. However, traditional means of functionalizing materials do not result in permanent effects, posing a difficulty in the textile business. For instance, washing e-textile-based clothes reduces the intended functional effects that have been given. Nanotechnology offers scope to help fabrics gain new and permanent functionality. The desired qualities can be obtained via nanotechnology without impacting the breathability or texture of textiles.

The fundamental problem in electronic textiles is to insert the required functionality element into the fabrics while maintaining the qualities of both parts. By principle, two geometrical characteristics, size and shape have profound impacts on unique chemical/physical characteristics, particularly at the nanometer scale. Single-dimensional (1D) materials like nanorods, nanobelts, nanowires, nanofibers and nanomaterials can operate like an electron highway in the axial orientation, improving carrier collecting and shortening the carrier transport route. Furthermore, 1D nanostructures offer outstanding mechanical characteristics, which are necessary for atomic-scale modification and manipulation. Also, 1-D nanomaterials can mix with many inorganic substances on the surface, as it is very wide.

Electrospun nanofibers

Wearable electronics are intended to be long-lasting, lightweight and flexible, properties synonymous with fiber-based construction. Several fiber architectures have been produced using low-cost and well-established textile processing procedures, and due to their hierarchical nature, these fibrous materials are ideal for fabricating wearable electronics.

The efficiency of batteries, supercapacitors and solar cells is dependent on the materials used as well as the manner of manufacturing. Generating the charge, transporting and collecting it, as well as dispersion are all part of the energy conversion and storage process. By serving as an electron highway in the axial direction, electrospun nanofibers can reduce the carrier transportation distance and improve the carrier collection capabilities. Low cost, high specific surface area, optical transparency and superior mechanical strength/flexibility are also special features of nanofibers, and conductive nanofibers have decent electrical conductivity. Such materials have a lot of promise for use in future generations of energy storage and conversion devices because of their transparency, high energy/power density, flexibility and mobility.

Manufacturing of electrospun nanofibers

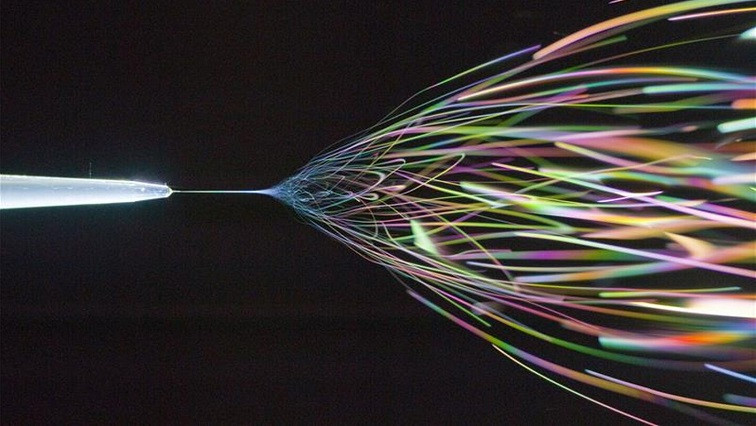

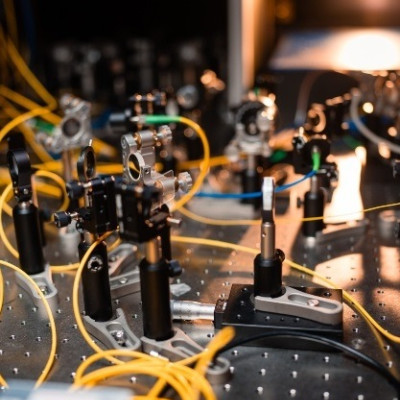

Electrospinning technology has been around for over 70 years and is the best way to fabricate continuous nanofibers. The nanofibers are developed in sub-micrometer sizes during electrospinning by applying an electrical force to polymer melts or solutions. Via a whipping-like motion, the electric force squeezes out polymer jets from a spinneret and extends them from millimeters to submicrometer widths. So, when electrostatic forces present among the spinneret and collector plate surpass the surface tension at the spinneret end, the polymer melt rushes toward the grounded collector plate. The polymer solution is whipped after leaving the spinneret and the solvent vanishes, leaving polymer fiber in solid form. The nanofibers clump together on the collecting plate and create nonwoven mats.

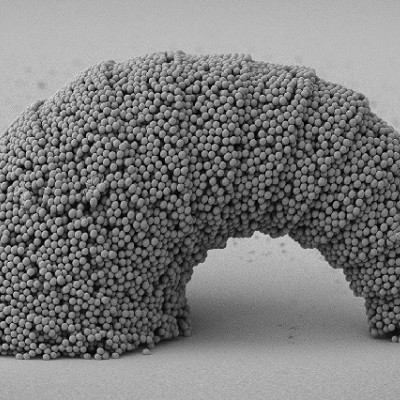

The electrospun nanofibers can be effortlessly functionalized by including nanoscale components into the spinning dope or altering the surface after the spinning process. For making conductive nanofibers, polymer solutions are often doped with nanoparticles or carbon nanotubes.

Application of electrospun nanofibers.

Conclusion

Electrospinning technology is a strong contender for producing cheap piezo/triboelectric nanofibers since numerous nanoparticles and materials are effectively manufactured as nanofibers and/or nanofibers with integrated nanoparticles. The traditional electrospinning methods are being altered for enhanced position controllability, viability to integrate nanoparticles and alignment. The resulting nanofibers have excellent flexibility and stretchability while also being cheap and extremely clothing-compatible e-textiles, and hence have a great potential for applications in wearable electronic devices, sensors and energy storage devices.

While electrospinning is a vital technology for creating 1D nanostructures, there are still several difficulties to be resolved before these materials can excel in terms of industrialization and practical applications. For instance, nanofibers with diameters less than 50 nm are difficult to obtain uniformly, and the manufacturing rate is poor.

Read the original article on GlobalSpec.