Graphene-enhanced concrete is a relatively new development and has been used in small-scale construction projects in the UK. However, a new initiative led by Climate Group in partnership with World GBC and WBCSD suggests the development and application of such technologies needs to ramp up considerably to meet emission targets with members of ‘Concrete Zero’ committing to using 100% net zero concrete by 2050. Current members including Laing O’Rouke, Wilmott Dixon and Joseph Homes are signed up to the initiative.

Portland cement is responsible for the characteristics that make concrete so widely used, but it also accounts for most of its carbon emissions, so the search is on to find alternative solutions that offer the same benefits with a lower environmental impact.

Despite being the strongest material ever discovered, graphene has struggled to become a heavy weight in commercial products. The main drawback has been the ability to mix graphene into other materials in volume.

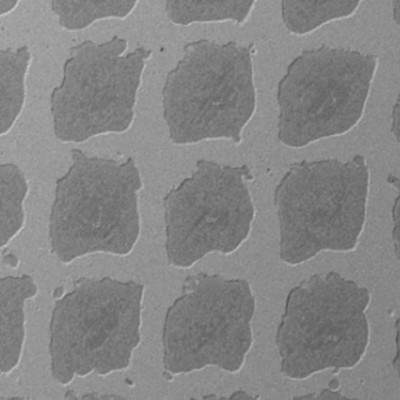

Graphene is water resistant and does not mix well with materials such as cement. For it to make friends with the material it is going into and to reach the top of its class in terms of performance, graphene must be dispersed uniformly – a process that can be tricky to achieve the desired result.

The work being undertaken between Atomi and Haydale will centre around functionalising graphene using the environmentally friendly and patented HDPlas process.

Unlike traditional and wet chemistry methods of getting graphene to perform, plasma functionalisation is a single stage, powder in, powder out process that does not produce any effluent streams and isn’t reliant on chemical treatment.

Haydale’s graphene can be blended easily with fine and coarse aggregate containing cement for making high-performance concrete with optimised physical and mechanical properties. Therefore, graphene enhanced concrete is expected to demonstrate better mechanical properties than non-graphenated products.

The work will select appropriate graphene grades and functional groups for achieving enhanced compatibility between the functionalised graphene and concrete raw materials. Significant improvements in mechanical as well as wear, corrosion, and moisture resistant properties are expected through this process. Advanced characterisation will be carried out to evaluate functionalised graphene powders and their impact on the physical properties of concrete.

Given the physical and mechanical strength characteristics of functionalised graphene, the addition can significantly reduce the cement content in concrete. In turn this reduces CO2 emissions from the physical material with less cement needed as well as for application with less vehicles needed to transport the material.

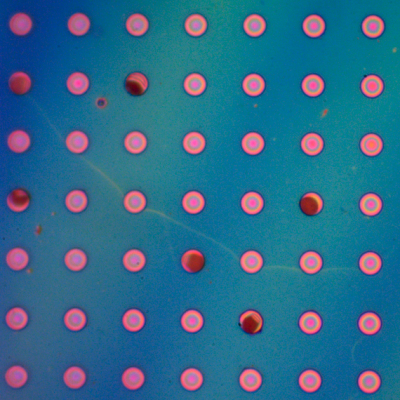

Smart technology is also being considered so that the graphene can be date stamped like the Hallmark seen on gold. Using sensor technology, it could be possible to gather real time data of a concrete structure, including its history and provide advanced warnings of things like deterioration. “With the advancements being made with graphene sensors we are looking at their use with digital readers to allow live feedback of the material so we can potentially monitor changes within the chemical structure of the cement,” explains Jason Laing, Atomi CEO.

Commenting on the partnership, Keith Broadbent, Haydale CEO said: “Haydale and Atomi have been working together since 2021 on the provision of functionalised nanomaterials in the biomedical sector. The possibility for advanced materials is so diverse and it is great to be starting this project with the potential to benefit a sector that increasingly is seeking alternative materials to improve products and reduce CO2 emissions.”

Project lead at Atomi, Director Simon Sokel added: “The construction industry is working extremely hard to make a significant reduction in CO2 emissions and we believe that what we are producing for concrete and other building materials will have a massive impact.”

It is hoped that the results of the project between Haydale and Atomi will be able to feed into the work of the Concrete Zero initiative in due course.

Read the original article on Haydale Graphene Industries.