Details of the novel system have just been published in one of the highest-ranking chemistry journals, Angewandte Chemie International Edition, featuring a laser-etched version of the famous Mona Lisa painting and micro-braille printing even smaller than a pin head.

“This could be a way to reduce the need for expensive, specialised equipment including high-power lasers with hazardous radiation risk, while also using more sustainable materials. For instance, the key polymer is made from low-cost elemental sulfur, an industrial byproduct, and either cyclopentadiene or dicyclopentadiene,” says Matthew Flinders Professor of Chemistry Justin Chalker, from the Flinders University.

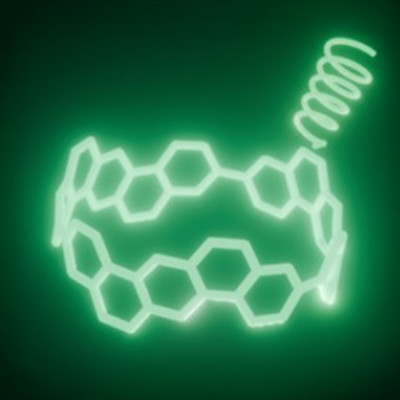

“Our study used a suite of lasers with discreet wavelengths (532, 638 and 786 nm) and powers to demonstrate a variety of surface modifications on the special polymers, including controlled swelling or etching via ablation.

“The facile synthesis and laser modification of these photo-sensitive polymer systems were exploited in applications such as direct-write laser lithography and erasable information storage,” says Dr Chalker from the Flinders University Institute for NanoScale Science and Engineering.

As soon as the laser light touches the surface, the polymer will swell or etch a pit to fashion lines, holes, spikes and channels instantly.

The discovery was made by Flinders University researcher and co-author Dr Christopher Gibson during what was thought to be a routine analysis of a polymer first invented in the Chalker Lab in 2022 by PhD candidate Samuel Tonkin and Professor Chalker.

Dr Gibson says: “The novel polymer was immediately modified by a low-power lasers – an unusual response I had never observed before on any other common polymers.

“We immediately realised that this phenomenon might be useful in a number of applications, so we built a research project around the discovery.”

Another Flinders College of Science and Engineering PhD candidate, Ms Abigail Mann, led the next stage of the project and is first-author on the new international journal paper.

“The outcome of these efforts is a new technology for generating precise patterns on the polymer surface,” she says.

“It is exciting to develop and bring new microfabrication techniques to sulfur-based materials. We hope to inspire a broad range of real-world applications in our lab and beyond.”

Potential applications include new approaches to storing data on polymers, new patterned surfaces for biomedical applications, and new ways to make micro- and nanoscale devices for electronics, sensors and microfluidics.

With support from research associate Dr Lynn Lisboa and Samuel Tonkin, the Flinders team conducted detailed analysis of how the laser modifies the polymer and how to control the type and size of modification.

Another co-author Dr Lisboa adds: “The impact of this discovery extends far beyond the laboratory, with potential use in biomedical devices, electronics, information storage, microfluidics, and many other functional material applications.

Flinders spectroscopist Dr Jason Gascooke, of the Australian National Fabrication Facility (ANFF), also worked on the project.

He says the latest discovery would not have been possible without the tools afforded by Federal and State Government funding for the national facilities of Microscopy Australia and the ANFF in SA, as well as Flinders Microscopy and Microanalysis.

The South Australian Node of the ANFF was established under the National Collaborative Research Infrastructure Strategy to provide micro and nanofabrication facilities for Australia’s researchers.

Read the original article on Flinders University.