What do volcanic lava, fire smoke, automobile exhaust fumes, and printer toner have in common? They are all sources of ultrafine particles – particles with a diameter below 100 nanometers, which can pose serious health risks if inhaled. Due to their small size, ultrafine nanoparticles are difficult to detect and measure without expensive and sometimes bulky equipment. To overcome these issues, our researchers have designed a new ultra-sensitive fiber-tip sensor that can detect single particles with diameters down to 50 nanometers in size. In the future, the new sensor will be used in studies to control and evaluate indoor air quality at schools.

Nanoparticles are very much part of the everyday world that we call home. For example, in medical testing, devices are available to check for nanoparticles like pathogens and biomarkers for diseases such as cancer.

And in drug development, a host of nanoparticles are used to make the drug delivery systems of the future.

One class of nanoparticle that is garnering plenty of attention due to its connection with the air that we breathe is the ultrafine particle (UFP), a particle with a diameter below 100 nanometers (nm).

Exposure to UFPs – which can be found in smoke, exhaust fumes, and even printer toners – can have serious health risks, especially if these particles are directly inhaled.

“When UFPs lodge in the lungs, it can pose a severe health risk because once in the lungs, they can absorb toxins that we might breathe in from the air around us. As a result, those toxins then stay in the body,” says Arthur Hendriks, PhD researcher at the Department of Applied Physics and Science Education. “So, to help prevent this, accurate ways of detecting UFPs are needed so as to monitor indoor air quality.”

For example, research on indoor air quality is at the forefront of the Horizon Europe project LEARN, which is seeking to control and evaluate indoor air quality at schools and to assess the impact of air quality on children’s health, and part of this requires accurate ways to detect UFPs.

The small-big problem

But detecting UFPs is easier said than done though, and ironically, detection of such small particles relies on the use of large and expensive equipment.

“Large and expensive isn’t the answer. We need small, compact, accurate, and cheap devices to make it easier to detect UFPs in factories, hospitals, offices, and schools,” notes Hendriks.

So, what is the state-of-the-art now then? “There are sensors based on fiber-optic technologies that can measure liquids and gases with good accuracy. But these sensors not suitable for measuring small particles like UFPs and so their application are limited in that sense,” says Hendriks.

‘Lab-on-fiber’ technologies have been used to detect biological cells at the micrometer scale (1000 times larger than the nanometer scale). “But this technology cannot detect single nanoparticles similar in size to UFPs,” says Hendriks.

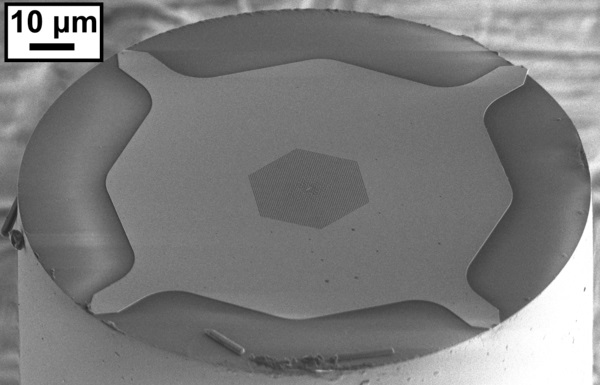

SEM image of nanophotonic fiber tip sensor.

A fiber-tip solution

To meet the demand for a new UFP sensing technology, Hendriks and his TU/e collaborators, which includes Andrea Fiore – professor at the Department of Applied Physics and Science Education, developed a nanophotonic fiber-tip sensor that is sensitive to tiny changes in the environment around the sensor, so much so that it can detect a single nanoparticle the same size as UFPs.

“Our sensor design is small and compact, and importantly, it clearly indicates when a detection has occurred,” says Hendriks.

The researchers’ sensor work is based on a photonic crystal, a periodic or repeating structure that can reflect light in all directions. “A defect, or error, is then added to the crystal, which is known as a photonic crystal cavity, or PhCC for short,” says Hendriks.

A PhCC allows light to be trapped in the crystal for an extended period. Hendriks: “In essence, this is something we call the Q-factor, which is a measure of how well light can be trapped in the defect over time. In our case, the light is confined to a tiny volume, which is below 1 µm3. This is known as the mode volume, and to measure tiny nanoparticles, this needs to be very small.”

The researchers were able to place the PhCC on the tip of a fiber using a method developed by Andrea Fiore’s group back in 2020. When a tiny particle comes close to the PhCC in the crystal, it disturbs the cavity by changing its refractive index. “So, the tiny particle changes the wavelength of the trapped light in the cavity, and we measure this change.”

Unprecedented sensitivity

“Our setup provides unprecedented sensitivity in comparison to previous technologies out there,” points out Hendriks. “Using the sensor, we were able to detect in real-time single UFPs with diameters as low as 50 nanometers. In my opinion, that’s just astounding!”

The next step for Hendriks and his colleagues is to suspend the cavities so that the quality factor and the coupling efficiency are even higher, which could result in nanophotonic cavities with best-in-class characteristics, but still readable through the fiber.

“Our approach could be used to detect even smaller particles. Or even in other applications like single-photon emitters and nano-optomechanical sensors,” says Hendriks. “And an additional application of the new approach might even be the detection of single biological molecules.”

Next up for the UFP sensor will be the European project LEARN, which aims at controlling and evaluating air quality at schools, and it will be done in collaboration with the Microsystems group at TU/e.

Further information

The full paper entitled “Detecting single nanoparticles using fiber-tip nanophotonics” can be read here.

Read the original article on Eindhoven University of Technology (TU/e).