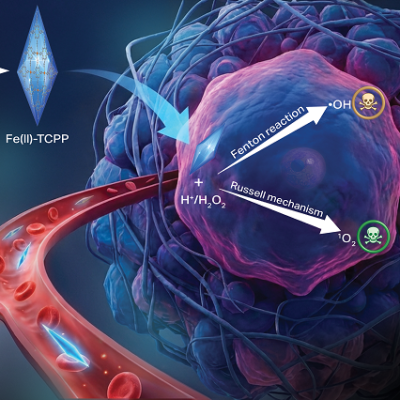

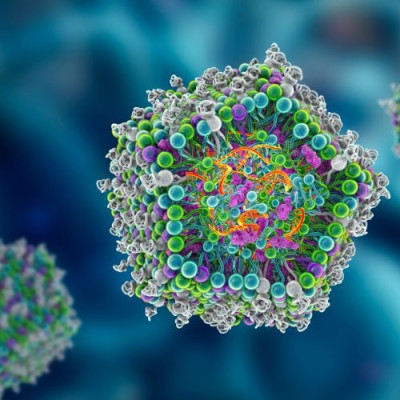

Liposomes have emerged as important vehicles for drug and gene delivery applications, due to liposomes mimicking cell behaviour and enabling their protection from the immune responses of the body.

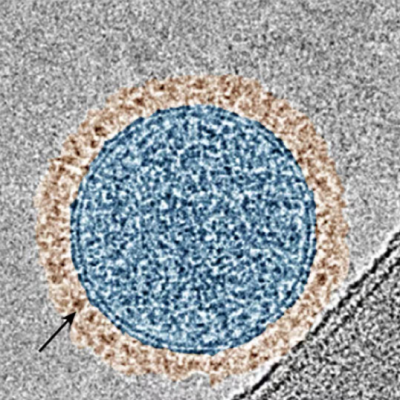

Now, researchers at Flinders University have developed a straightforward process for fabricating liposomes under continuous flow processing in the VFD.

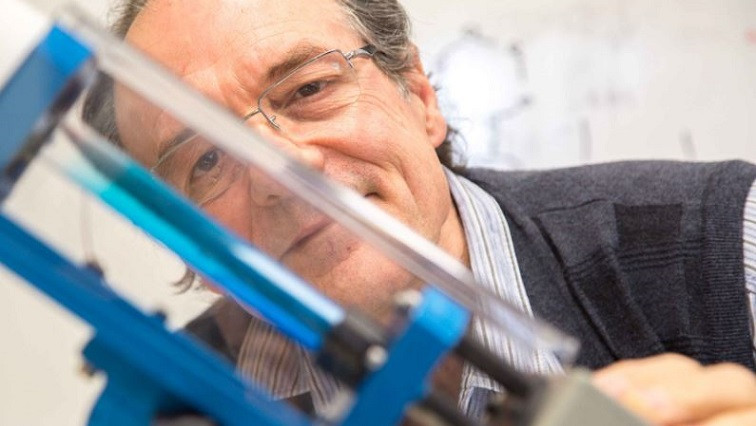

Since 2013, Professor Raston has worked with his team in the Raston Lab at Flinders University to explore the possibilities of the VFD, which is capable of controlling chemical reactivity, materials processing and probing the structure of self-organised systems, enabling rapid and predictable modifications.

The VFD has already shown itself capable of synthesising esters, amides, ureas, imines, alpha-amino phosphates, beta-Keto esters, modified amino acids and lidocaine, a local anaesthetic.

The new approach with the VFD represents a paradigm shift in fabricating liposomes, with the ability to control their dis-assembly and re-organization without any need for further processing.

The research – ‘Vortex fluidic regulated phospholipid equilibria involving liposomes down to sub-micelle size assemblies’, by Nikita Joseph, Marzieh Mirzamani, Tarfah Abudiyah, Ahmed Hussein Mohammed Al-Antaki, Matt Jellicoe, David Harvey, Emily Crawley, Clarence Chuah, Andrew Whitten, Elliot Paul Gilbert, Shuo Qian, Lilin He, Michael Michael, Harshita Kumari and Colin Raston – has been published in Nanoscale Advances.

This paper comes on the back of further published research on the Vortex Fluidic Device that highlights the many diverse fields that this extraordinary thin film microfluidic platform has impacted since its inception.

The paper – ‘Thin-film flow technology in controlling the organization of materials and their properties’, by Clarence Chuah, Xuan Luo, Javad Tavakoli, Youhong Tang and Colin Raston – has been published in the Special Collection: Distinguished Australian Researchers edition of Aggregate journal.

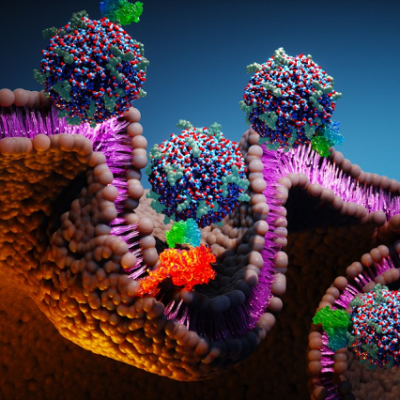

“Nanotechnology is revolutionary, and its hype is justified, especially for improving the quality of human life with novel consumer products through various materials and manufacturing methods,” says Professor Raston.

“The distinct applicable transformations suggest that the VFD can impart on a wide variety of transformations with reduced laborious handling.”

VFD advantages over conventional batch processing of nano-materials include fluidic waves causing high shear and producing large surface areas for micro-mixing as well as rapid mass and heat transfer, enabling reactions beyond diffusion control.

“Combining these abilities allows for a ‘green’ and innovative approach to altering materials for various research and industry applications by controlling small-scale flows and regulating molecular and macromolecular chemical reactivity, self-organization phenomena, and the synthesis of novel materials,” says Professor Raston.

Thee published review highlights the aptitude of the VFD as clean technology, with an increase in efficiency for many novel material transformations that benefit from effective vortex-based processing to control material structure-property relationships.

“Through this novel device, we aim to reformulate how matter could be organized in precise ways using fluid flow mechanical induced effects, in striving toward accessing advanced materials, all the while circumventing any adverse effects of the engineered particles on the environment and human health,” says Professor Raston.

“This includes adhering to the principles of green chemistry, right through to the product being in the marketplace – and importantly it reduces the use of toxic materials and the production of waste in the processing.”

Read the original article on Flinders University.