This new approach is not only faster and safer than traditional methods, but also showcases the potential for eco-friendly chemical processes in industrial applications.

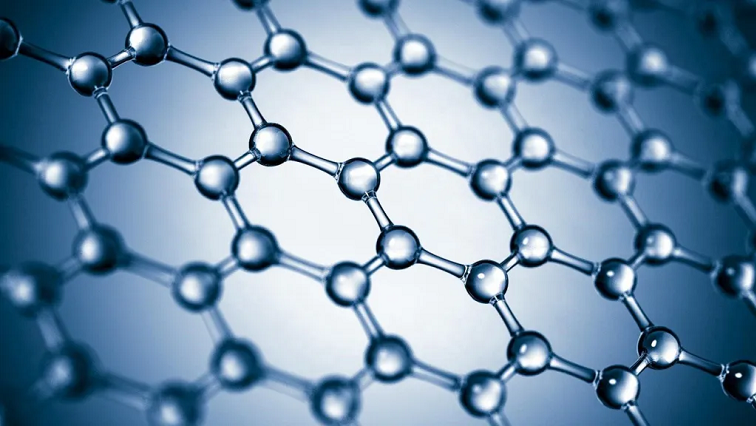

According to a varsity press release, graphene, a two-dimensional wonder material, gained global fame in 2010 when Sir Andre Geim and Sir Konstantin Novoselov from the University of Manchester were awarded the Nobel Prize for its discovery. It is celebrated for its potential to transform industries such as electronics, drug delivery, touch screens, paints, energy storage, and water purification.

The magic of graphene lies in its exceptional strength and outstanding electrical and thermal conductivity. However, its practical use is often hindered by its poor solubility in common solvents. This limitation is overcome by bromographene, a modified form of graphene that enhances its chemical reactivity and versatility.

Traditionally, synthesising bromographene has been challenging, requiring harsh conditions like high temperatures, high pressures, and hazardous chemicals such as liquid bromine. These methods pose significant safety risks and are time-consuming and environmentally unfriendly.

The research, led by Prof Dipak Sinha from the Department of Chemistry, Nagaland University, Prof Dinesh Rangappa from the Department of Applied Sciences (Nanotechnology), Visvesvaraya Technological University, and their PhD student Suraj Kumar, introduces a new method for preparing bromographene.

Kumar is also a recipient of the INSPIRE fellowship sponsored by the Department of Science and Technology, Government of India, and their work has earned them a German utility model IPR. Their method uses a safer brominating agent called tetrabutylammonium tribromide to convert reduced graphene oxide into bromographene.

This process is completed in just one hour, the fastest time reported so far, and it avoids the need for harsh conditions, making it much safer and more environmentally friendly. This new approach not only speeds up the production process but also achieves one of the highest reported bromine contents, making it useful for further chemical modifications. This can lead to new advancements in electronics, composites, and other high-tech materials.

By focusing on creating safer and faster production methods, the researchers from Nagaland University were leading the way toward sustainable innovations in material science, promising a future where high-performance materials can be produced without compromising safety or the environment, stated the release.

Read the original article on Nagaland Post.