From Insects to Biomedical Applications

For years, researchers knew that cicada wings had unique properties, including shedding water and debris. In 2012, researchers in Australia found that the cells killed bacteria as well. They demonstrated it with a type of bacteria that is particularly resistant to antibiotics.

To microbiologists, this was an intriguing one-two punch. Medical devices are routinely sterilized with chemical antibiotics that kill off bacteria. But they can’t clean the dead cells off of surfaces. Unfortunately, dead bacteria and other biological waste make the surface dangerously attractive to even more bacteria. For example, about half of the bacterial infections in blood in long-term health care facilities are from urinary tract infections caused by biowaste on catheters. A technology that could both kill and clean off microbes could be a game-changer.

Building and Testing the Pillars

Before you can imitate something in nature, you have to know how it works. The Australian researchers figured out that the process involved tiny structures in the wings called nanopillars. These are cylinders that are slightly taller and wider than one-thousandth of the width of a human hair. However, the process remained unknown.

That’s where scientists from Stony Brook University came in. About a decade later, they investigated how to replicate these nanostructures and their function outside of cicadas.

First, they needed to recreate the structures. Polymers – materials made of chains of repeating building blocks – are ideal for creating tiny structures. They also make up the plastics all around us. In part because of its ubiquity, the researchers chose polystyrene – also known as Styrofoam.

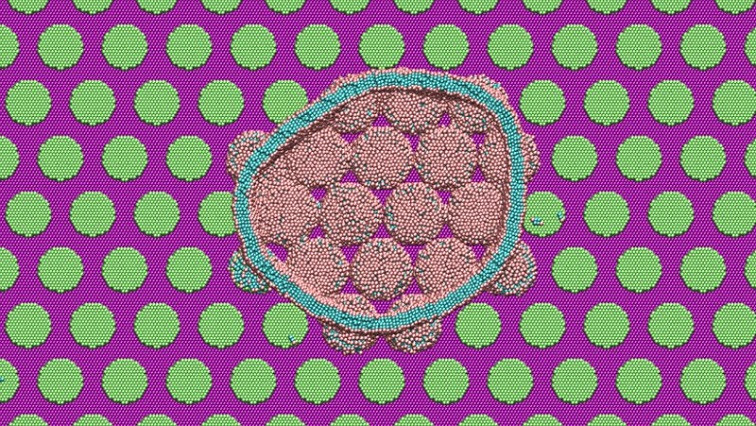

To create the tiny structures, the scientists used a nanoscience technique called directed self-assembly. In addition to their own lab, the scientists used the tools at the Center for Functional Nanomaterials, a DOE Office of Science user facility at Brookhaven National Laboratory. This technique can make dense, consistent patterns at the nanoscale level. With this process, scientists create the right environment for a certain type of polymer to arrange itself into patterns. Imagine the line blocks in Tetris moving into place, exactly where you want them to go. To analyze the patterns, the scientists tapped the resources at the National Synchrotron Light Source II user facility, also at Brookhaven National Laboratory.

The result? Tiny, squat cylinders that sat perpendicular to the surface they were grown on. To some of the pillars, the scientists also added a coating of titanium oxide. This material interacts with bacteria more than polystyrene does.

Then came the big question – do the synthetic structures destroy bacteria as well as the natural ones? To find out, the researchers soaked the structures in a nasty microbial “broth” for 36 hours. Needless to say, this broth wasn’t edible. One liquid was full of E. coli while the other was full of Listeria monocytogenes – both of which can cause severe illness.

The test was a success! Acting as both assassins and clean-up crew, the nanopillars both killed and eliminated the bacteria. In contrast, the flat surfaces made of the same materials didn’t. The one difference was that the structures that had a coating were more effective than those without one. While the polystyrene-only pillars effectively killed E. coli, they couldn’t handle the listeria. In contrast, the coated pillars killed and cleaned off both.

Digging into the Process

But the question remained as to why the pillars behave the way they do, whether natural or synthetic. The scientists hypothesized that perhaps the pillars pierced the membrane of the bacteria’s cell wall.

To find out, the scientists needed expertise and access to tools that could run large-scale, high-resolution molecular dynamics simulations. Experts at the Office of Science’s user facility Center for Nanophase Materials Sciences at DOE’s Oak Ridge National Laboratory stepped up. They assisted the team in running simulations on what was at the time the world’s most powerful supercomputer, Summit at the Oak Ridge Leadership Computing Facility (OLCF). (It’s since been surpassed by OLCF’s own Frontier, among other computers.) Summit can create simulations of incredibly complex systems. Simulating how part of the cell’s membrane interacted with representative pillars involved simulating more than a million particles!

What came back from the simulations surprised the scientists. The nanopillars weren’t piercing the cell membranes at all! In fact, it was a completely different process than expected.

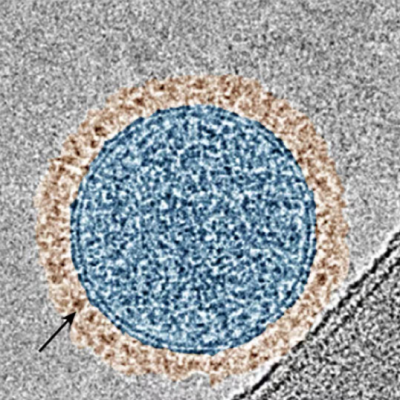

In reality, the process relies heavily on cell membranes’ structure. Cell membranes are made of two layers of lipids (fats, oils, and similar molecules). When the bacteria’s cell membrane touches the nanopillar, the head of the lipid attaches to the pillar. As it moves down the pillar, it draws the rest of the membrane along with it. As it covers the whole pillar, the membrane stretches out more and more – like a balloon. Eventually, the stress is too much and the membrane shatters.

Another surprise was that even though the scientists’ nanopillars were a different height than the natural ones, they were actually more effective. Knowing this will allow the scientists to decide on the ideal height.

Now the team is examining issues that may come up in medical applications. DOE’s Office of Science has provided the team with additional support through the Biopreparedness Research Virtual Environment (BRaVE) initiative. This funding helps build the nation’s ability to respond to biological threats. The researchers from Stony Brook University are continuing their work with the Center for Nanophase Materials Sciences at ORNL.

Studying insect wings may seem like research that couldn’t possibly apply to everyday humans’ lives. But with the support of the DOE’s resources and expertise, one day, medical patients may benefit from cicadas’ marvelous antibacterial properties.

Read the original article on US Department of Energy.