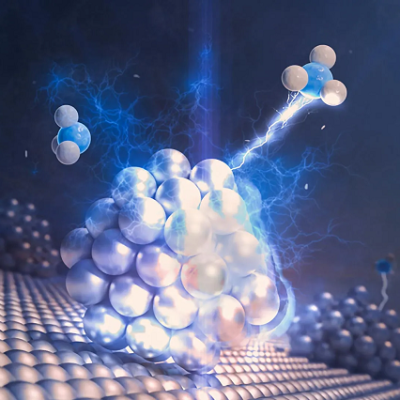

Industrial electrochemical processes that use electrodes to produce fuels and chemical products are hampered by the formation of bubbles that block parts of the electrode surface, reducing the area available for the active reaction. Such blockage reduces the performance of the electrodes by anywhere from 10 to 25 percent.

But new research reveals a decades-long misunderstanding about the extent of that interference. The findings show exactly how the blocking effect works and could lead to new ways of designing electrode surfaces to minimize inefficiencies in these widely used electrochemical processes.

It has long been assumed that the entire area of the electrode shadowed by each bubble would be effectively inactivated. But it turns out that a much smaller area — roughly the area where the bubble actually contacts the surface — is blocked from its electrochemical activity. The new insights could lead directly to new ways of patterning the surfaces to minimize the contact area and improve overall efficiency.

The findings are reported today in the journal Nanoscale, in a paper by recent MIT graduate Jack Lake PhD ’23, graduate student Simon Rufer, professor of mechanical engineering Kripa Varanasi, research scientist Ben Blaiszik, and six others at the University of Chicago and Argonne National Laboratory. The team has made available an open-source, AI-based software tool that engineers and scientists can now use to automatically recognize and quantify bubbles formed on a given surface, as a first step toward controlling the electrode material’s properties.

Industrial electrochemical processes that use electrodes to produce fuels and chemical products are hampered by the formation of bubbles that block parts of the electrode surface, reducing the area available for the active reaction. Such blockage reduces the performance of the electrodes by anywhere from 10 to 25 percent.

But new research reveals a decades-long misunderstanding about the extent of that interference. The findings show exactly how the blocking effect works and could lead to new ways of designing electrode surfaces to minimize inefficiencies in these widely used electrochemical processes.

It has long been assumed that the entire area of the electrode shadowed by each bubble would be effectively inactivated. But it turns out that a much smaller area — roughly the area where the bubble actually contacts the surface — is blocked from its electrochemical activity. The new insights could lead directly to new ways of patterning the surfaces to minimize the contact area and improve overall efficiency.

The findings are reported today in the journal Nanoscale, in a paper by recent MIT graduate Jack Lake PhD ’23, graduate student Simon Rufer, professor of mechanical engineering Kripa Varanasi, research scientist Ben Blaiszik, and six others at the University of Chicago and Argonne National Laboratory. The team has made available an open-source, AI-based software tool that engineers and scientists can now use to automatically recognize and quantify bubbles formed on a given surface, as a first step toward controlling the electrode material’s properties.

Read the original article on Massachusetts Institute of Technology (MIT).