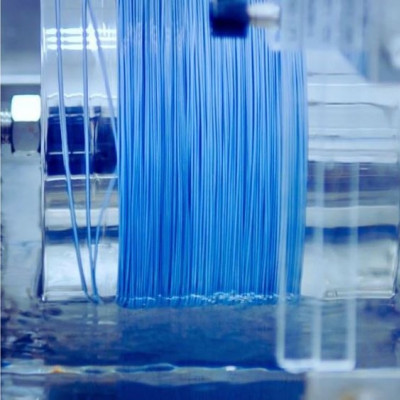

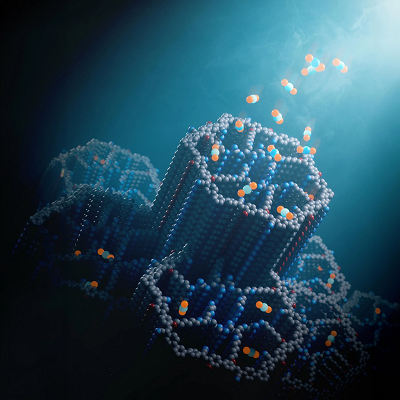

Nanoporous membranes with atomic-scale holes smaller than one-billionth of a meter have powerful potential for decontaminating polluted water, pulling valuable metal ions from the water, or for osmotic power generators.

But these exciting applications have been limited in part by the tedious process of tunneling individual sub-nanometer pores one by one.

“If we are to ever scale up 2D material membranes to be relevant for applications outside the laboratory, the ‘one pore at a time’ method just isn't feasible,” said recent UChicago Pritzker School of Molecular Engineering (PME) PhD graduate Eli Hoenig. “But, even within the confines of laboratory experiment, a nanoporous membrane provides significantly larger signals than a single pore, increasing the sensitivity.”

Hoenig is first author of a paper recently published in Nature Communications that found a novel path around this longstanding problem. Under PME Asst. Prof. Chong Liu, the team created a new method of pore generation that builds materials with intentional weak spots, then applies a remote electric field to generate multiple nanoscale pores all at once.

“Our logic is that, if we can pre-design what the material looks like and design where the weak points are, then when we do the pore generation, the field will pick up those weaker points and start to drill holes there first,” Liu said.

The strength of weakness

By overlapping a few layers of polycrystalline molybdenum disulfide, the team can control where the crystals met.

“Say I have two perfect crystals. When the two crystals come together, they will not be smoothly just glued together. There's an interface where they start to connect to each other,” Liu said. “That’s called the grain boundary.”

This means they can “pre-pattern” the grain boundaries—and the pores that will eventually form there—with a remarkable level of control.

But it isn’t just location that can be fine-tuned through this technique. The concentration of the pores and even their sizes can be determined in advance. The team was able to tune the size of the pore from 4 nanometers to smaller than 1 nanometer.

This allows flexibility for engineering water treatment systems, fuel cells or any number of other applications.

“People want to precisely create and confine pores, but usually the method is limited so that you can only create one pore at a time,” Liu said. “And so that's why we developed a method to create high-density pores where you are still able to control the precision and size of each individual pore.”

While the technique has a number of uses, Hoenig finds the environmental applications most exciting. These include treating water and extracting valuable materials such as the lithium needed for the grid-scale batteries demanded by the world’s transition to renewable energy.

“Targeted water decontamination and resource recovery are, at least at this basic science level, two sides of the same coin, and both, to me, are really important,” Hoenig said.

Liu said this new paper is an intellectual offshoot of an interdisciplinary collaboration with the battery-focused laboratory of PME Prof. Shirley Meng and PME Asst. Prof. Shuolong Yang’s quantum group. Working across academic silos, the three labs previously collaborated to break through a longstanding hurdle in growing quantum qubits on crystals.

“Our three teams are trying to develop precision synthesis techniques, not only for one type of material and not only for one type of material property,” Liu said. “Together, we are looking at how we can manipulate a material’s composition, structure, and defects to be able to create precise defects and pores.”

Liu is commercializing the work with the University of Chicago Polsky Center for Entrepreneurship and Innovation.

Read the original article on University of Chicago.