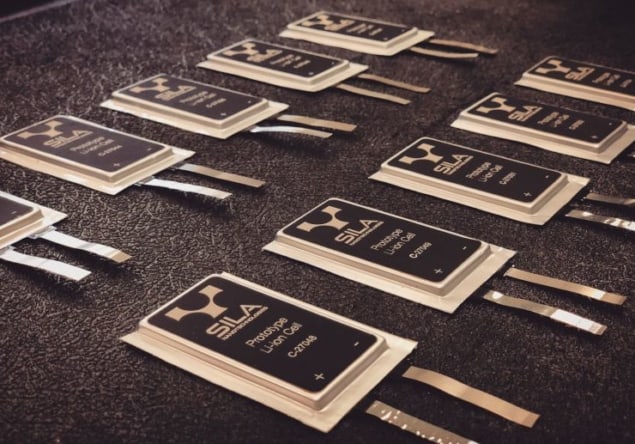

Prototype lithium-ion cells made by Sila Nanotechnologies, which the company claims have a 20-40% higher energy density than conventional cells. Image courtesy of Sila Nanotechnologies.

Prototype lithium-ion cells made by Sila Nanotechnologies, which the company claims have a 20-40% higher energy density than conventional cells. Image courtesy of Sila Nanotechnologies.

Silicon nanomaterials that squeeze 40% more energy into batteries. A smart watch that gives people with diabetes a pain-free way of tracking their blood glucose levels. “Smart” sensors that help prevent repetitive strain injuries and diagnose faults in remote equipment. A replacement for toxic chemicals in flame-retardant materials. These are just a few examples of the innovations discussed in Berlin last week at IDTechEx Europe, an annual conference that focuses on some of the hottest topics in science and technology.

On 10 April, while the rest of the physics community (judging from Twitter, at least) was cooing over the first image of a black hole, scientists from two start-up companies, SiLiB and Sila Nanotechnologies, outlined their plans for manufacturing lithium-ion batteries with silicon anodes instead of conventional graphite ones. The idea of replacing graphite with other materials, including silicon, isn’t new, and it’s easy to see why it’s attractive: the specific capacity (roughly, how much energy a material can store) of silicon is 4200 milliamp hours per gram (mAh/g), compared to graphite’s measly 372 mAh/g. Other factors, such as the make-up of the cathode, limit the expected improvement in storage capacity to 40% rather than a factor of 10, but that’s still significant. I’d love it if my mobile phone battery lasted 40% longer, and an electric car that travelled 40% further between charges would be a game-changer for many consumers.

There’s a problem, though: silicon anodes swell and shrink by up to 300% during charge-discharge cycles, causing irreversible damage to the battery. SiLiB’s solution is to make its anodes from silicon nanowires grown on an ultrathin stainless-steel mesh that is flexible enough to cope with the swelling. The results seem promising: CEO Arnon Blum presented data showing that SiLiB’s batteries retain 70% of their capacity after 300 charge cycles, and there were audible sighs of disappointment from the audience when he said that the product is still in development.

Sila Nanotechnologies, in contrast, hopes to launch its first commercial product later in 2019, albeit for smart watches rather than the electric vehicles its CEO (Gene Berdichevsky, an early Tesla employee) had in mind when he co-founded the company in 2011. Sila’s anodes are made from a silicon-dominant nanocomposite material, and while the company’s business-development manager, Craig Weich, declined to give details (“My slides were a lot more interesting before our IP folks reviewed them,” he joked), the basic idea is that the nanocomposite incorporates enough space in its structure for the silicon to swell inside it. According to Weich, the main thing delaying the material’s commercial roll-out is that it’s difficult to manufacture it in large quantities – which is why Sila is targeting the market for smart watches rather than mobile phones or electric vehicles.

Pain-free glucose monitoring

Another company hoping for a piece of the smart-watch market is PKVitality, a Paris, France-based start-up that aims to give people with diabetes a pain-free way of monitoring their blood glucose levels. PKVitality’s smart watch fits over (and communicates with) an adhesive patch containing millimetre-long microneedles that sample the interstitial fluid in the upper layers of the skin. This interstitial fluid reacts with glucose oxidase enzyme in the patch, liberating electrons and making it possible to infer blood glucose values from the resulting electric current. Because nerves in the wrist are more than 1mm below the surface, PKVitality CEO and founder Luc Pierart claims that applying the patch is no more painful than running a fingernail over the skin – a huge improvement over the several-times-daily fingerprick tests that most people with diabetes use to monitor blood sugar.