| Date | 30th, Jul 2019 |

|---|

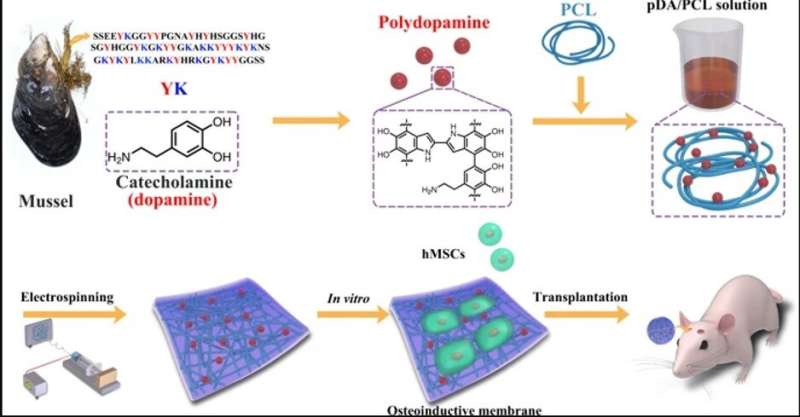

Schematic drawing of the fabrication of the engineered membranes via electrospinning of PCL and PDA NPs. Credit: NPG Asia Materials, doi: 10.1038/s41427-019-0139-5

Schematic drawing of the fabrication of the engineered membranes via electrospinning of PCL and PDA NPs. Credit: NPG Asia Materials, doi: 10.1038/s41427-019-0139-5

In a new study now published on NPG Asia Materials, bioengineers report the development of a new fibrous membrane with stem cells to repair bone defects in the skulls of mice. For this, they incorporated mussel-inspired polydopamine protein as a promising compound to tether biological substances to the membrane surfaces, much like adhesive proteins in mussels. In the work, Yi Deng and a research team in the interdisciplinary departments of chemical engineering, mechanical engineering, materials technology, center for future materials and regenerative medicine in China and Australia, coated the biocompatible membranes with polydopamine nanoparticles to form many topological sites for calcium attachment and bone defect repair.

The team incubated the uncoated and coated membranes with stem cells isolated from bone marrow and implanted the membranes to regenerate skull bone defects in live mice. After a 2-month translational study, they revealed the ability of the sticky membranes to direct stem cells to produce significantly higher quantities of bone, compared with uncoated membranes. Bone defects and injuries can commonly occur at the microscopic level as congenital defects, due to accidents or as age-related degenerative disease. Most bone defects cannot be repaired spontaneously by self-healing mechanisms leading to an urgent requirement to develop robust biomaterials that facilitate bone repair in bone research and bone tissue engineering.

Bioengineers can manipulate stem cell differentiation to form mature osteoblasts via guided tissue regeneration (GTR) on surface membranes for optimized, large-scale bone regeneration. In materials science and advanced functional materials, electrospun membranes have received massive attention for such guided tissue engineering strategies due to several biocompatible advantages, including:

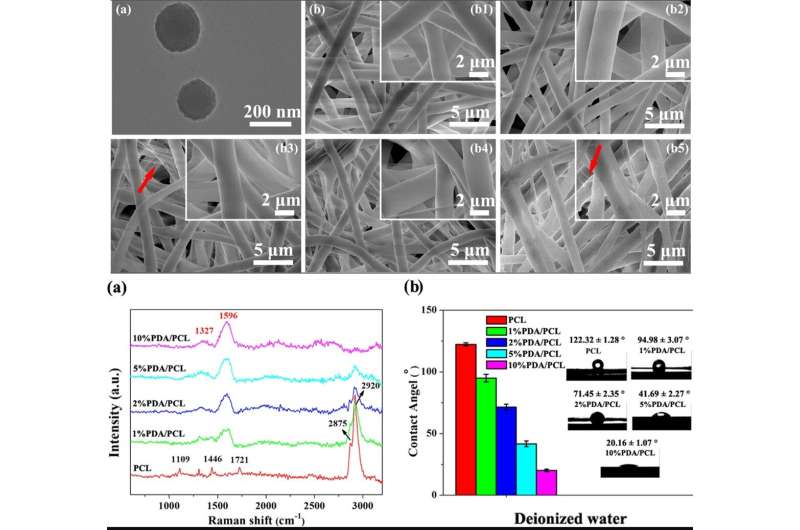

Biomimicry for stem cell attachmentLarge surface area to facilitate cell adhesion and growthThe ability to form 3-D fibrous membranes and accelerate the osteogenic potential of numerous stem cell lines (from mouse, rat and human species). TOP: Micro-morphologies of PDA NPs and electrospun PDA/PCL fibrous membranes. a TEM image of PDA NPs; b SEM images of the (b1) pristine PCL, (b2) 1% PDA/PCL, (b3) 2% PDA/PCL, (b4) 5% PDA/PCL, and (b5) 10% PDA/PCL fibrous membranes. The red arrows in b point to the filaments. BOTTOM: Chemical constituents of PDA/PCL fibrous membranes. (a) Raman spectra and (b) contact angles with corresponding water droplet images of PDA/PCL fibrous membranes. Credit: NPG Asia Materials, doi: 10.1038/s41427-019-0139-5

TOP: Micro-morphologies of PDA NPs and electrospun PDA/PCL fibrous membranes. a TEM image of PDA NPs; b SEM images of the (b1) pristine PCL, (b2) 1% PDA/PCL, (b3) 2% PDA/PCL, (b4) 5% PDA/PCL, and (b5) 10% PDA/PCL fibrous membranes. The red arrows in b point to the filaments. BOTTOM: Chemical constituents of PDA/PCL fibrous membranes. (a) Raman spectra and (b) contact angles with corresponding water droplet images of PDA/PCL fibrous membranes. Credit: NPG Asia Materials, doi: 10.1038/s41427-019-0139-5

Materials scientists classify synthetic GTR materials into two main categories as (1) bioabsorbable and (2) nonabsorbable materials; where nonabsorbable materials must be removed after implantation via a second surgery, causing increased healthcare expenses, while compromising newly generated tissue. In contrast, biodegradable membranes such as polyvinyl alcohol (PVA), poly (lactide-co-glycolide) (PLGA) or PCL are preferred for clinical implantations, although biological complications have seriously impeded their clinical adoption.

In the present work, therefore, Deng et al. used the bioinspired adhesive protein secreted from mussels as a 'material-independent' and facile surface coating, engineering strategy based on catechol chemistry. Polydopamine (PDA) can facilitate osteoblastic differentiation of stem cells on a variety of substrates as a nanoscale biomaterials coating, to support mesenchymal stem cell attachment and induce reprogramming of human somatic cells. Nevertheless, PDA nanolayers can easily delaminate from surfaces to induce local cell apoptosis or inflammatory reactions as adverse effects. Deng et al. implemented specific experimental steps to overcome the existing limitations and develop a new biocompatible and biodegradable membrane in the lab. The newly engineered biomaterial or fibrous membrane will provide a favorable niche to steer the fates of local stem cells to form osteoblasts for bone regeneration.

Step one: Engineering PDA-included PCL (PDA/PCL) with electrospinning

The scientists used catechol chemistry for PDA/PCL fibrous membrane fabrication and synthesis. They uniformly dispersed the PDA nanoparticles (NPs) in PCL via continuous sonication and vortexing to form the fibrous membranes via electrospinning. Deng et al. used a scanning electron microscope (SEM) and observed surface properties of the random, micron-sized fibrous network. Comparatively, the pure PCL electrospun membranes remained smooth, whereas the integration of PDA NPs made the fiber surfaces rough. The scientists confirmed the new surface chemistry using Raman spectra and X-ray photoelectron spectroscopy (XPS) analysis. The biomaterials were hydrophilic allowing protein adsorption and cell attachment. The researchers conducted contact angle measurements to verify surface wettability and improved hydrophilicity after PDA modification compared to the pure, unmodified PCL membranes.

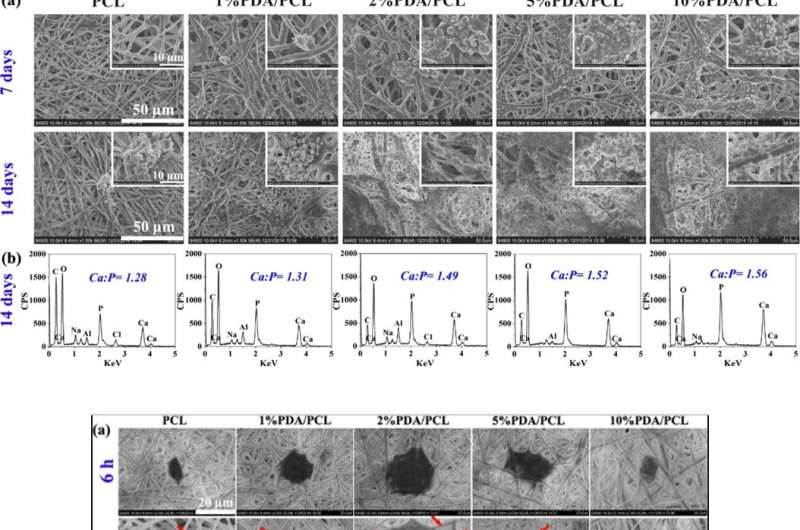

TOP: Bone-like nodules formation. (a) SEM photographs of PDA/PCL fibrous membranes acquired after soaking in SBF for 7 and 14 days. (b) EDS data and Ca/P ratios of the particle sediments on the surface of PDA/PCL fibrous membranes at 14 days. BOTTOM: Cell attachment and proliferation. (a) SEM and b CLSM observation of adhering hMSCs on the engineered fibrous membranes with different PDA NP concentrations at 6 and 12 h. The red arrows in a point to the pseudopodia. The inserts in the upper right of (b) show the magnified images of a single cell. (c) Cell attachment and (d) proliferation curves of hMSCs on the sample surfaces obtained via CCK-8. * Represents p

TOP: Bone-like nodules formation. (a) SEM photographs of PDA/PCL fibrous membranes acquired after soaking in SBF for 7 and 14 days. (b) EDS data and Ca/P ratios of the particle sediments on the surface of PDA/PCL fibrous membranes at 14 days. BOTTOM: Cell attachment and proliferation. (a) SEM and b CLSM observation of adhering hMSCs on the engineered fibrous membranes with different PDA NP concentrations at 6 and 12 h. The red arrows in a point to the pseudopodia. The inserts in the upper right of (b) show the magnified images of a single cell. (c) Cell attachment and (d) proliferation curves of hMSCs on the sample surfaces obtained via CCK-8. * Represents p