| Date | 3rd, Nov 2022 |

|---|

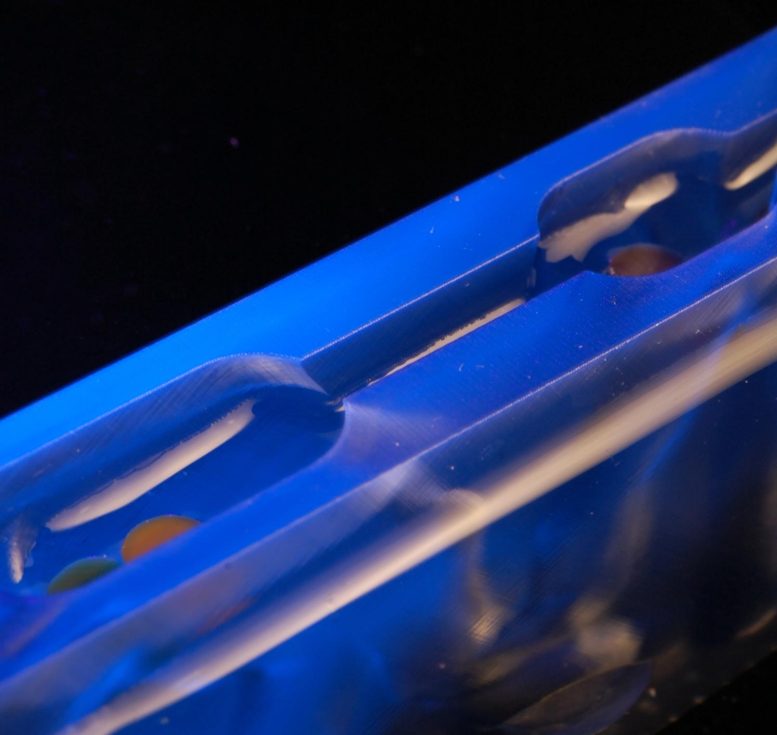

This simple machine that uses the surface tension of water to grab and manipulate microscopic objects. Credit: Manoharan Lab/Harvard SEAS

A 3D-printed device in a tank of water braids nanowires and moves microparticles.

New antennae to access higher and higher frequency ranges will be needed for the next generation of phones and wireless devices. One way to make antennae that work at tens of gigahertz — the frequencies needed for 5G and higher devices — is to braid filaments about 1 micrometer in diameter. However, today’s industrial fabrication techniques won’t work on fibers that small.

“It was a shout-out-loud-in-joy moment when — on our first try — we crossed two fibers using only a piece of plastic, a water tank, and a stage that moves up and down.” — Maya Faaborg

Now a team of engineers and scientists from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) has developed a simple machine that uses the surface tension of water to grab and manipulate microscopic objects. This remarkable innovation offers a potentially powerful tool for nanoscopic manufacturing.

The research was published in the journal Nature on October 26.

“Our work offers a potentially inexpensive way to manufacture microstructured and possibly nanostructured materials,” said Vinothan Manoharan, the Wagner Family Professor of Chemical Engineering and Professor of Physics at SEAS and senior author of the paper. “Unlike other micromanipulation methods, like laser tweezers, our machines can be made easily. We use a tank of water and a 3D printer, like the ones found at many public libraries.”

The machine is a 3D-printed plastic rectangle that is about the size of an old Nintendo cartridge. The interior of the device is carved with channels that intersect. Each channel has wide and narrow sections, similar to a river that expands in some parts and narrows in others. The channel walls are hydrophilic, meaning they attract water.

Through a series of simulations and experiments, the scientists discovered that when they submerged the device in water and placed a millimeter-sized plastic float in the channel, the surface tension of the water caused the wall to repel the float. If the float was in a narrow section of the channel, it moved to a wide section, where it could float as far away from the walls as possible.